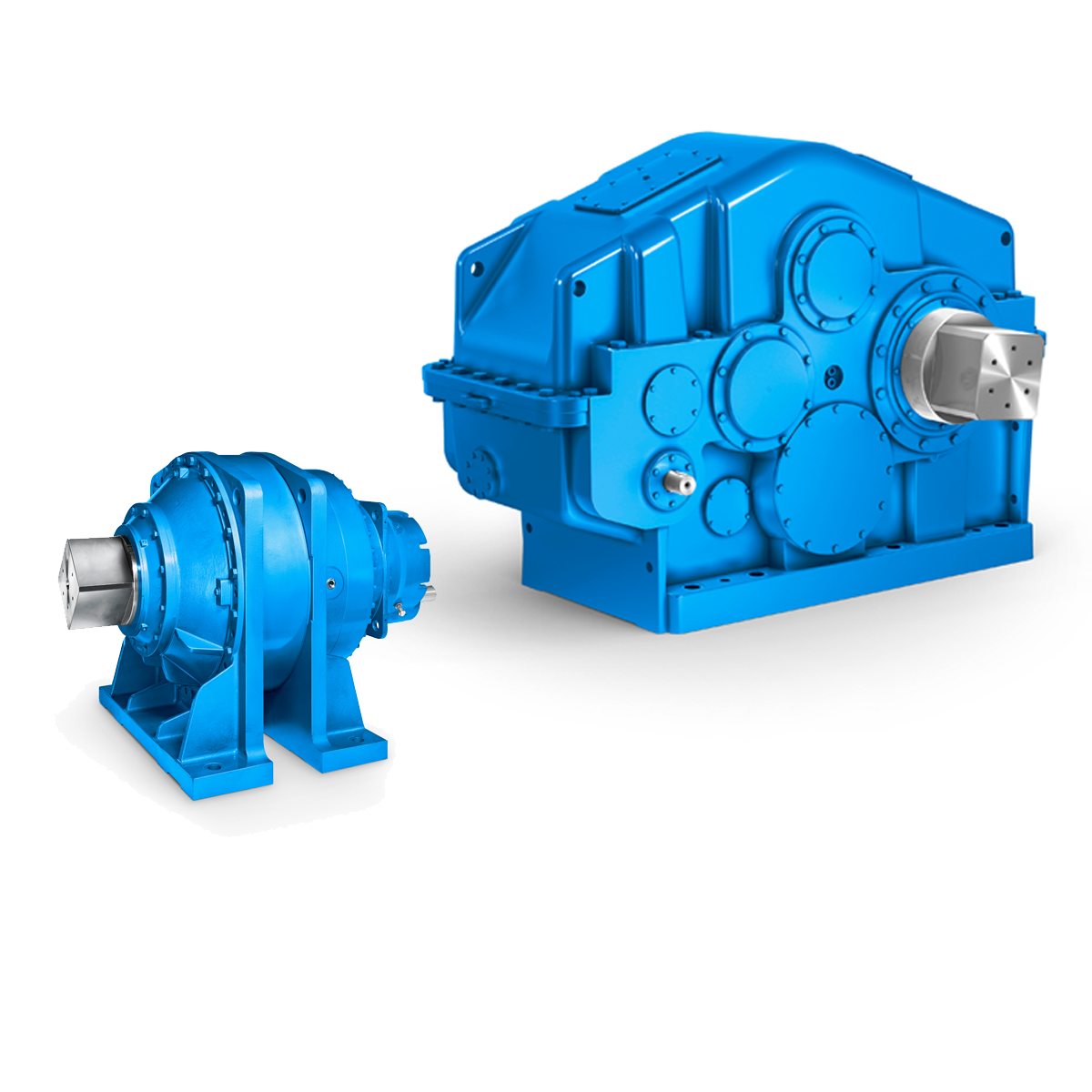

Product Description

Helical Gearbox inline helical gear box bevel worm reduction Shaft Mounted parallel manufacturers industrial coaxial 2 stage unit crane duty Helical Gearbox

helical concentric gearbox speed reducer decelerator has the features of high versatility,good combination and heavy loading capability, along with other merits such as easy to attain various transmission ratios, high efficiency, low vibrationand high permissible axis radial load. This series can not only be combined with various kinds of reducers and variators and meet the requirements, but also beadvantage of localization of related transmission equipment.

1) Output speed: 0.6~1,571rpm

2) Output torque: up to 18,000N.m

3) Motor power: 0.18~160kW

4) Mounted form: foot-mounted and flange-mounted mounting

| Product Name | SLR Series Rigid Tooth helical reducer |

| Gear Material | 20CrMnTi |

| Case Material | HT250 |

| Shaft Material | 20CrMnTi |

| Gear Processing | Grinding finish by HOFLER Grinding Machines |

| Color | Customized |

| Noise Test | Bellow 65dB |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery |

|---|---|

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | – |

| Type: | – |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Troubleshooting Gearbox Issues in a Sugar Mill

When encountering gearbox issues in a sugar mill, a systematic troubleshooting approach can help identify and address the underlying problems. Here’s a step-by-step guide:

- Visual Inspection: Start by visually inspecting the gearbox for any obvious signs of damage, leaks, or wear.

- Check Lubrication: Ensure that the gearbox is properly lubricated with the correct type and amount of lubricant.

- Temperature Check: Monitor the gearbox temperature during operation, as overheating can indicate issues.

- Vibration Analysis: Conduct vibration analysis to detect any abnormal vibration patterns that might point to misalignment or other problems.

- Check Alignment: Verify the alignment of the gearbox components and shafts to prevent issues caused by misalignment.

- Bearing Inspection: Examine the condition of bearings for wear, pitting, or other signs of damage.

- Address Noise: Investigate any unusual noises, as they might indicate gear damage or other issues.

- Examine Seals: Check the seals and gaskets for damage that could lead to leaks or contamination.

- Review Operational Data: Analyze operational data and compare it to expected performance to identify deviations.

- Consult Experts: If issues persist or are complex, consider consulting gearbox experts or manufacturers for guidance.

Remember that proper maintenance, timely repairs, and regular inspections are essential to keep sugar mill gearboxes running smoothly and to prevent costly downtime.

Benefits of Using a High-Quality Gearbox in a Sugar Mill

A high-quality gearbox plays a crucial role in the efficient and reliable operation of a sugar mill. Here are some key benefits of using a high-quality gearbox:

- Improved Efficiency: High-quality gearboxes are designed with precision and manufactured using advanced techniques, resulting in smoother and more efficient power transmission. This helps optimize the overall performance of the sugar mill.

- Enhanced Reliability: High-quality gearboxes are built to withstand the rigorous demands of sugar mill operations. They are constructed using durable materials and undergo strict quality control measures, leading to increased reliability and reduced downtime.

- Increased Lifespan: A well-designed and well-manufactured gearbox has a longer lifespan due to its resistance to wear, fatigue, and breakdown. This translates to lower maintenance costs and longer intervals between replacements.

- Precise Output: Sugar mill operations require precise control over the speed and torque of the machinery. High-quality gearboxes ensure accurate and consistent output, contributing to the quality and quantity of sugar production.

- Reduced Maintenance: High-quality gearboxes require less frequent maintenance due to their durability and resistance to wear. This leads to cost savings in terms of labor, replacement parts, and production downtime.

- Minimized Downtime: Gearbox failures can lead to significant production downtime. High-quality gearboxes are less prone to breakdowns, reducing the chances of unexpected downtime and production interruptions.

- Energy Efficiency: High-quality gearboxes are designed to minimize energy losses due to friction and inefficiencies. This contributes to energy savings and cost reduction in the long run.

- Consistent Performance: High-quality gearboxes maintain consistent performance even under varying load conditions and harsh operating environments, ensuring a steady production process.

- Advanced Features: Some high-quality gearboxes come with advanced features such as noise reduction, vibration dampening, and built-in safety mechanisms, further enhancing their value and benefits.

Overall, investing in a high-quality gearbox for a sugar mill results in improved operational efficiency, reduced maintenance costs, and a more reliable and productive sugar production process.

Working Principle of a Sugar Mill Gearbox

A sugar mill gearbox operates on the principles of power transmission and torque conversion to facilitate the processing of sugarcane into sugar and related products. The gearbox functions as a mechanical device that changes the speed and torque characteristics of the input power source, typically an electric motor, to meet the specific requirements of the sugar extraction and processing machinery.

Here’s how a sugar mill gearbox works:

- The input power from the electric motor is transmitted to the gearbox, which contains a set of gears designed to achieve the desired speed reduction and torque increase.

- The high-speed input rotation is transformed by the gearbox’s gears into a lower speed while simultaneously increasing the torque output.

- The high torque output is then utilized to drive the heavy rollers, crushers, and other equipment within the sugar mill.

- The rotating motion of the gearbox gears ensures that the rollers and crushers crush and grind the sugarcane to extract sugar juice efficiently.

- The extracted sugar juice is further processed and refined to produce the final sugar product.

The sugar mill gearbox’s ability to convert high-speed, low-torque input power into low-speed, high-torque output power is essential for effectively processing sugarcane and achieving optimal extraction results. Its precise and reliable operation ensures the efficient functioning of the sugar mill and contributes to the overall productivity of the sugar industry.

editor by CX 2024-04-17