Product Description

PROFESSIONAL MANUFACTURE

— SINCE 1995

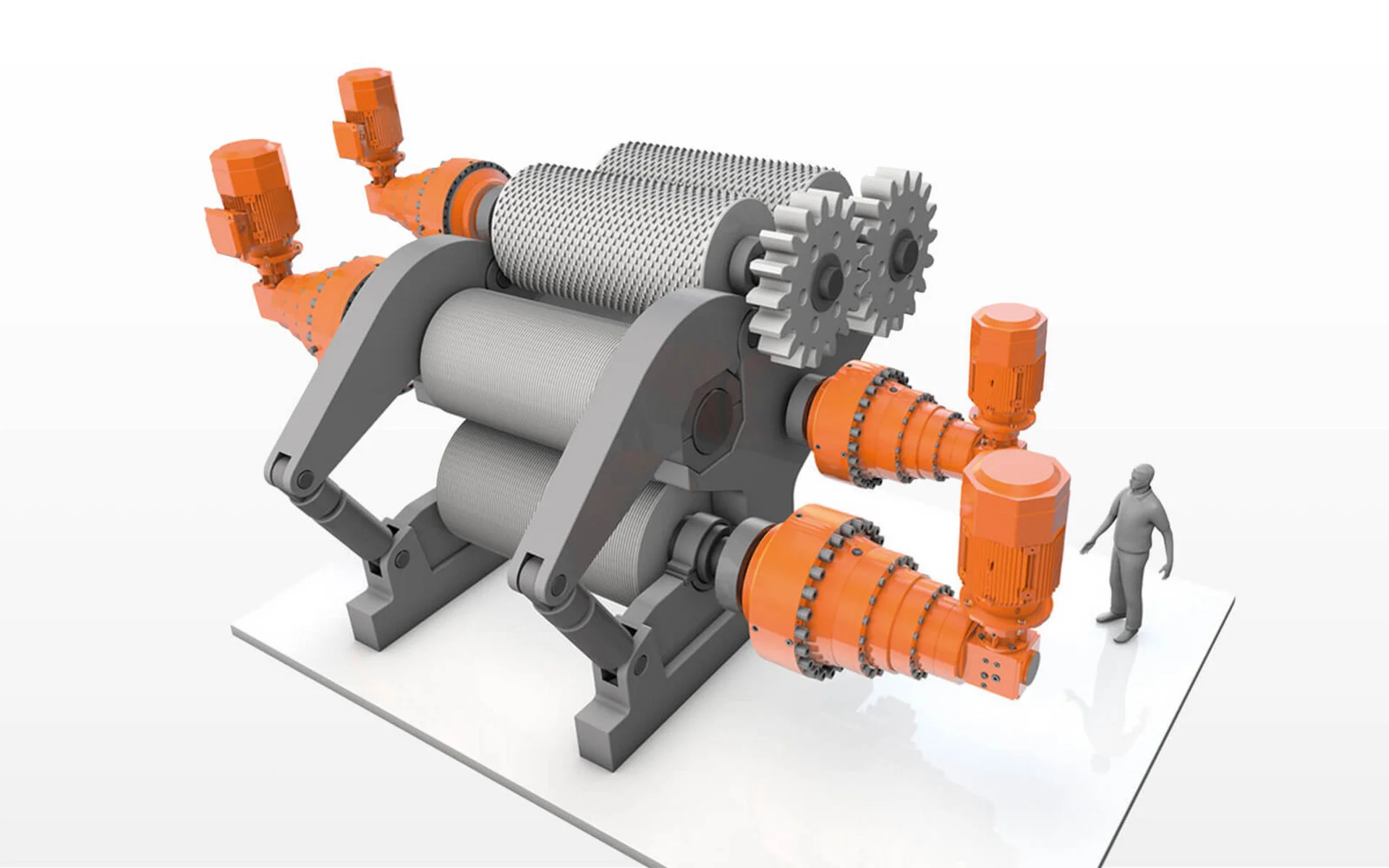

P series heavy duty industrial planetary gear unit gearbox for sugar mill machine

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light

industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

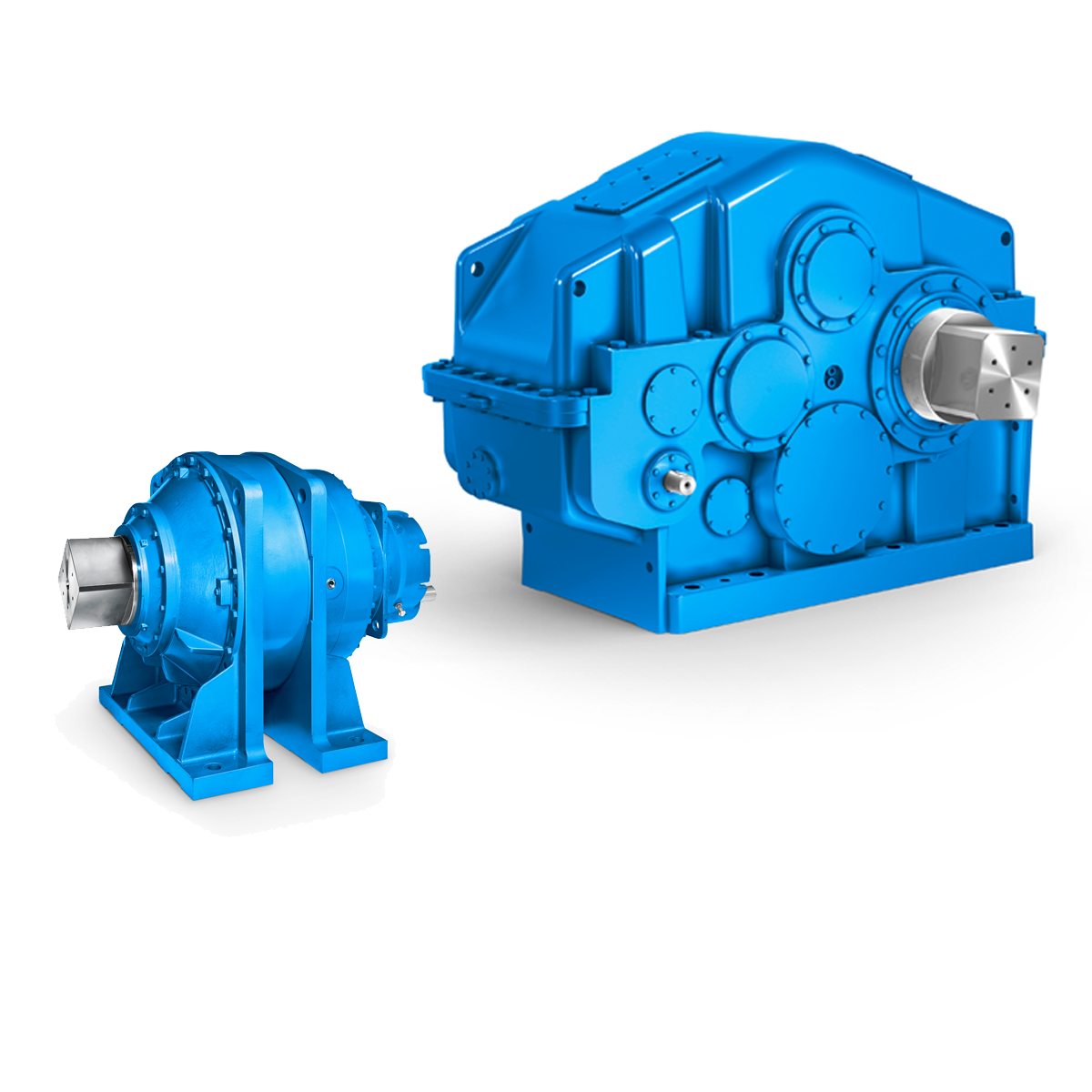

Main Series Product: R series helical gear motor reducer, K series spiral bevel gear reducer, NGW, P series planetary gear reducer, H B series helical gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gearbox reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloidal speed reducer, etc. Meanwhile, map sample processing business can be undertaken.

Product Description

Adopts modular design, which can be changed and combined according to customer requirements;

Adopts involute planetary gear transmission, uses internal and external meshing and power splitting;

The gears are all treated by carburizing and quenching to obtain a high-hard wear-resistant surface.

After heat treatment, the gears are all ground, which reduces noise and improves the efficiency and service life of the whole machine.

Light weight, small volume, large transmission ratio range, high efficiency, stable operation, low noise and strong adaptability.

Product Parameters

|

Size |

Type |

Transmission Ratio |

Type |

Transmission Ratio |

|

|

9/10/11/12/13/14/ |

P2NA/P2NB/ |

25/28/31.5/40 |

P3NA/P3NB/P3NC/P3ND |

140/160/180/ |

N=Coaxial S=Helical gear L=Bevel gear K=Bevel-helical A=Hollow shaft with shrink disc B=Solid shaft with parallel key C=Hollow shaft with involute splines D=Solid shaft with involute splines

|

|

P2SA/P2SB/ |

45/50/56/63 |

P3SA/P3SB/P3SC/P3SD |

280/315/355/400 |

||

|

P2LA/P2LB/ |

31.5/40/45/50 |

P3KA/P3KB/P3KC/P3KD |

560-4000 |

||

|

P2KA/P2KB/ |

112/125/140/160/ |

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. industrial helical gearbox.

Detailed Photos

Chinese Speed Reducer/industrial helical gearbox is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products.

Packaging & Shipping

Application

| Driven machines | |||

| Waste water treatment | Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps | Dredgers | Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry | Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges | Metal working mills | plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CZPT mills |

| Metal working mills | Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives | Conveyors | Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters | Reciprocating compressors | ||

| Cranes | Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes | Cooling towers | Cooling tower fans, blowers axial and radial |

| Cane sugar production | Cane knives, cane mills | Beet sugar production | Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines | Pulper drives | Cableways | Material ropeways, continuous ropeway |

| Cement industry | Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers | ||

Company Profile

Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look CZPT to speaking with you to future discuss how we can be of service to you.

FAQ

1. Who are we?

We are the Factory, with over 25 years of production experience, based in ZheJiang , China, start from 1995,sell to Domestic Market(50.00%),Mid East(10.00%),Southeast Asia(10.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),Eastern Asia(5.00%),North America(3.00%),Africa(2.00%),Southern Europe(2.00%),South Asia(2.00%),Central America(1.00%).

2. Can you customize according to our requirements?

Yes, we can design nonstandard products according to customer’s drawing and sample.

3.What can you buy from us?

speed reducer,gearbox,gear motor,pump,crusher

4. Why should you buy from us not from other suppliers?

Founded in 1995, with over 20 years of production experience and credibility. With professional engineer team, advanced technology production and skilled workers.Specialized in the production of reducer. Map sample processing business can be undertaken.

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,DDU,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Application: | Motor, Machinery, Manufacturing Plant |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | Order Sample heavy duty industrial planetary gear unit gearbox

|

|---|

| Customization: |

Available

| Customized Request |

|---|

Average Lifespan of a Sugar Mill Gearbox

The average lifespan of a sugar mill gearbox can vary widely depending on several factors, including the quality of the gearbox, maintenance practices, operating conditions, and the load it experiences. However, in general, a well-designed and well-maintained sugar mill gearbox can have a lifespan of 15 to 20 years or more.

Sugar mill gearboxes are subjected to demanding operating conditions, including high loads, shock loads, and continuous operation during the sugarcane crushing season. As a result, proper maintenance and regular inspections are essential to extend the lifespan of the gearbox.

Key factors that influence the lifespan of a sugar mill gearbox include:

- Quality of Manufacturing: Gearboxes manufactured with high-quality materials and precision engineering are more likely to have a longer lifespan.

- Maintenance Practices: Regular maintenance, lubrication, and inspection can help identify and address issues before they escalate and lead to gearbox failure.

- Load and Operating Conditions: Gearboxes operating under heavy loads or in harsh conditions may experience more wear and have a shorter lifespan.

- Lubrication: Proper lubrication is crucial to reducing friction and wear within the gearbox components, which can significantly impact its lifespan.

It’s important for sugar mills to work closely with gearbox manufacturers, adhere to recommended maintenance schedules, and invest in high-quality gearboxes to ensure a longer and reliable operational life.

Eco-Friendly and Energy-Efficient Gearbox Options for Sugar Mills

Sugar mills are increasingly seeking eco-friendly and energy-efficient gearbox solutions to reduce their environmental impact and operational costs. Here are some options:

- High-Efficiency Gear Designs: Choose gearboxes with advanced designs that optimize efficiency and reduce energy losses during transmission.

- Variable Frequency Drives (VFDs): Pair gearboxes with VFDs to control motor speed and torque according to the load requirements. This minimizes energy consumption during partial loads.

- Regenerative Braking: Some gearbox systems incorporate regenerative braking mechanisms that capture and reuse energy during deceleration, further improving efficiency.

- Better Lubrication: Use high-quality, energy-efficient lubricants that reduce friction and heat generation, improving overall gearbox efficiency.

- Sealing Solutions: Implement effective sealing solutions to prevent lubricant leakage and contamination, which can lead to increased friction and energy losses.

- Integrated Cooling Systems: Choose gearboxes equipped with efficient cooling systems that dissipate heat effectively, ensuring optimal operating temperatures.

- Condition Monitoring: Implement advanced condition monitoring systems that track gearbox performance and identify inefficiencies or issues that can lead to energy waste.

- Modern Materials: Select gearboxes manufactured using modern materials that provide higher strength and durability, reducing wear and energy losses.

- Efficient Manufacturing Processes: Opt for gearboxes produced using energy-efficient manufacturing methods that minimize resource consumption and waste.

- Green Initiatives: Collaborate with gearbox manufacturers who prioritize sustainability and environmental responsibility in their production processes.

By considering these options, sugar mills can adopt more eco-friendly and energy-efficient gearbox solutions, contributing to both environmental conservation and cost savings.

Working Principle of a Sugar Mill Gearbox

A sugar mill gearbox operates on the principles of power transmission and torque conversion to facilitate the processing of sugarcane into sugar and related products. The gearbox functions as a mechanical device that changes the speed and torque characteristics of the input power source, typically an electric motor, to meet the specific requirements of the sugar extraction and processing machinery.

Here’s how a sugar mill gearbox works:

- The input power from the electric motor is transmitted to the gearbox, which contains a set of gears designed to achieve the desired speed reduction and torque increase.

- The high-speed input rotation is transformed by the gearbox’s gears into a lower speed while simultaneously increasing the torque output.

- The high torque output is then utilized to drive the heavy rollers, crushers, and other equipment within the sugar mill.

- The rotating motion of the gearbox gears ensures that the rollers and crushers crush and grind the sugarcane to extract sugar juice efficiently.

- The extracted sugar juice is further processed and refined to produce the final sugar product.

The sugar mill gearbox’s ability to convert high-speed, low-torque input power into low-speed, high-torque output power is essential for effectively processing sugarcane and achieving optimal extraction results. Its precise and reliable operation ensures the efficient functioning of the sugar mill and contributes to the overall productivity of the sugar industry.

editor by CX 2023-09-04