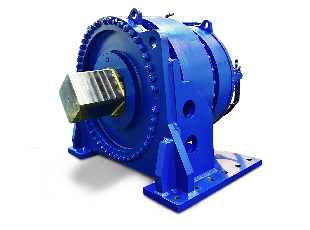

Product Description

Spiral Bevel Helical Gearbox Box 90 Degree High-Quality Transmission Right Angle Speed Reducer Alloy Steel Stainless Induction Straight Spiral Bevel Gearboxes

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Materials Used to Manufacture Sugar Mill Gearboxes

Sugar mill gearboxes are subjected to demanding operating conditions, including heavy loads and varying temperatures. To ensure durability and performance, the following materials are commonly used in the manufacture of sugar mill gearboxes:

- Cast Iron: Cast iron is a popular choice for gearbox housings due to its high strength and resistance to wear. It provides a sturdy and reliable casing for internal components.

- Steel Alloys: High-quality steel alloys are used for gears and shafts to provide excellent strength, durability, and resistance to fatigue. Alloy steel ensures that gears can withstand the stresses and loads encountered in sugar mill operations.

- Bronze: Bronze is often used for bearings and bushings due to its self-lubricating properties and resistance to corrosion. Bearings made from bronze help reduce friction and extend the lifespan of the gearbox.

- Aluminum: Aluminum alloys are sometimes used for components that require lightweight construction, such as casings and covers. Aluminum’s corrosion resistance and relatively low weight make it suitable for specific gearbox parts.

- Other Alloys: Depending on specific requirements, other alloys and materials may be used for specialized components within sugar mill gearboxes to ensure optimal performance and longevity.

The choice of materials depends on factors such as the gearbox’s intended application, operating conditions, load capacity, and the level of wear and corrosion resistance required. Engineers and manufacturers carefully select materials to ensure that sugar mill gearboxes can endure the challenges of the sugar production process.

Noise Levels in Sugar Mill Gearboxes

The noise levels associated with sugar mill gearboxes can vary depending on various factors such as the type of gearbox, the design of the gears, the quality of manufacturing, and the operating conditions. Sugar mill gearboxes are often subjected to heavy loads and high speeds, which can contribute to higher noise levels. The noise generated by gearboxes is typically categorized into two main components:

- Mechanical Noise: This is the noise produced due to the interaction of gear teeth as they mesh and transmit power. The impact and sliding between gear teeth can result in vibrations and noise. Helical and bevel gearboxes tend to generate less mechanical noise compared to straight-toothed gears.

- Aerodynamic Noise: In some cases, the movement of air around the gearbox can contribute to noise generation. This can be more pronounced in open or poorly enclosed gearbox designs.

To mitigate noise levels, manufacturers implement various techniques:

- Precision Manufacturing: High-quality manufacturing processes result in gears that mesh more smoothly, reducing impact and vibration.

- Gear Tooth Design: Optimized gear tooth profiles, such as helical or spiral bevel gears, can help minimize noise by promoting smoother meshing.

- Lubrication: Proper lubrication is crucial to reducing friction and noise. High-quality lubricants and effective lubrication systems can help dampen noise levels.

- Enclosures: Well-designed gearbox enclosures and housings can help contain noise and prevent the transmission of vibrations.

- Vibration Damping: Adding vibration-damping materials or features can help absorb vibrations and reduce noise transmission.

It’s important to note that while efforts can be made to reduce gearbox noise, it’s challenging to completely eliminate it due to the nature of gear interactions. Regular maintenance, monitoring, and following manufacturer’s recommendations can help ensure optimal performance and noise levels.

Maintenance of a Sugar Mill Gearbox

Maintaining a sugar mill gearbox is crucial to ensure its optimal performance, longevity, and reliable operation throughout the demanding sugar milling process. Proper maintenance practices involve the following steps:

- Regular Inspection: Perform routine visual and physical inspections of the gearbox to identify any signs of wear, damage, or leaks. Check for unusual noises, vibrations, and temperature changes, which can indicate potential issues.

- Lubrication: Ensure proper lubrication of gears, bearings, and other moving parts. Follow the manufacturer’s guidelines for lubricant type, quantity, and change intervals. Clean the gearbox and replace lubricants as needed.

- Tightening and Alignment: Regularly check and tighten bolts, fasteners, and couplings to maintain proper alignment and prevent misalignments that can lead to premature wear.

- Seal Inspection: Check seals and gaskets for leaks and deterioration. Replace damaged seals to prevent lubricant leakage and contamination.

- Vibration Analysis: Conduct vibration analysis to detect early signs of misalignment, imbalance, or other mechanical issues. Address any imbalances promptly to prevent further damage.

- Temperature Monitoring: Monitor gearbox temperature during operation. Abnormal temperature increases can indicate overloading or inadequate lubrication.

- Cleaning: Keep the gearbox and its surroundings clean and free from debris, dust, and contaminants. Regular cleaning helps prevent the buildup of foreign particles that can affect gearbox performance.

- Expert Inspection: Periodically engage professional technicians or engineers to perform in-depth inspections, measurements, and assessments of the gearbox’s condition. They can identify potential issues that may not be apparent during routine checks.

- Record Keeping: Maintain detailed records of maintenance activities, inspections, and repairs. This documentation helps track the gearbox’s history and allows for better planning of future maintenance.

- Training: Ensure that maintenance personnel are properly trained in gearbox maintenance procedures and safety protocols.

By following a comprehensive maintenance routine, sugar mill operators can extend the lifespan of their gearboxes, prevent unexpected downtime, and ensure the consistent and efficient operation of the sugar milling process.

editor by CX 2024-04-24