Product Description

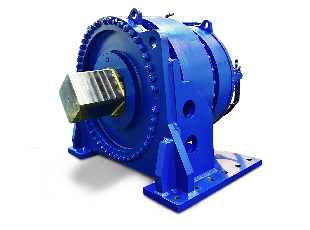

JWB Series Speed Variator

1. Features:

JWB-X type

- Sizes: ≥04

- Power up to 1.5 kW or more

- Cases in RAL 5571 blue cast iron

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2-10r/min;4.7-23.5r/min;15-75r/min;20-100r/min, 28-140r/min, 30-150r/min;40-200r/min;60-300r/min;80-400r/min;100-500r/min;190-950r/min.

- Output Torque value max 1002Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control handwheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

JWB-X B type

- Sizes:01,02,03 and 04

- Power up to 1.5 kW or less

- Cases in die-cast aluminium alloy

- Shafts: case hardened and tempered steel.

- Internal components: heat-treated steel

- Output speed with 4 pole(1400r/min) motors: 2r/min-20r/min;4.7r/min-23.5r/min;6.5-32.5r/min, 8-40r/min, 9-45r/min, 13-65r/min, 15r/min-75r/min;18-90r/min, 25-125r/min, 28r/min-140r/min;40r/min-200r/min;60r/min-300r/min;80r/min-400r/min;100r/min-500r/min;190r/min-950r/min.

- Output Torque value max 795 Nm

- Silent, vibration-free running

- Bidirectional rotation

- Control hand wheel positionable on either side

- Slipping speed to max load at 5%

- Regulation sensibility: 0,5 rpm

- Painted with blue epoxy-polyester powder

2. Technical parameters

| Type | Output Torque | Output Shaft Dia. | Output Speed Range | 2rpm-950rpm | |

| SWB01 | 2.6-1.6N.m | φ11 | Applicable Motor Power | 0.18kW-7.5kW | |

| SWB02 | 258-1.8N.m | φ14,φ24,φ28,φ32 | |||

| SWB03 | 426-4N.m | φ24,φ28,φ38 | Input Options | With Inline AC Motor | |

| SWB04 | 795-8N.m | φ28,φ38,φ42 | With IEC Motor | ||

| SWB05 | 535-16N.m | φ38,φ48,φ55 | With Input Shaft | ||

| SWB06 | 1002-40N.m | φ42,φ55,φ70 | With Input Flange | ||

About Us

ZheJiang CHINAMFG Drive Co.,Ltd,the predecessor was a state-owned military mould enterprise, was established in 1965. CHINAMFG specializes in the complete power transmission solution for high-end equipment manufacturing industries based on the aim of “Platform Product, Application Design and Professional Service”.

Starshine have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our Team

Quality Control

Quality:Insist on Improvement,Strive for Excellence With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of excellence

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective

measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend;

found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state.

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of

customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the

product is a product inspection to determine the qualified products.

7. Certification.

Packing

Delivery

| Application: | Motor, Machinery, Agricultural Machinery, Dumbwaiter, Sugar Mills, and Kinds of Equipments |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Lower Rotation Speed |

| Layout: | Speed Variator |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Choosing the Right Gearbox for a Sugar Mill

Choosing the right gearbox for a sugar mill is a critical decision that involves considering various factors to ensure optimal performance and reliability. Here are the key steps and considerations:

- Load Requirements: Evaluate the torque and load requirements of the sugar mill’s operation, including the crushing process and other associated machinery.

- Gearbox Type: Determine the appropriate type of gearbox based on the application. For sugar mills, helical or planetary gearboxes are commonly used due to their ability to handle heavy loads and provide smooth operation.

- Ratio and Speed: Calculate the required gear ratio and output speed to match the sugar mill’s operational needs and maximize efficiency.

- Power Transmission: Consider the power transmission capabilities of the gearbox to ensure it can efficiently transfer power from the prime mover (e.g., electric motor) to the mill’s machinery.

- Durability: Opt for gearboxes made from high-quality materials and robust construction to withstand the harsh conditions and high loads of sugar mill operations.

- Lubrication: Select a gearbox with proper lubrication systems and cooling mechanisms to prevent overheating and ensure smooth operation.

- Maintenance: Choose a gearbox that offers ease of maintenance, including access to components for inspection, lubrication, and potential repairs.

- Manufacturer Reputation: Work with reputable gearbox manufacturers known for producing reliable and durable products.

- Customization: Consider if the gearbox needs any customization to fit specific mill requirements or space limitations.

Collaborate with gearbox experts and manufacturers who specialize in industrial applications like sugar mills to ensure you choose a gearbox that meets your performance needs and contributes to the overall efficiency of your operations.

Noise Levels in Sugar Mill Gearboxes

The noise levels associated with sugar mill gearboxes can vary depending on various factors such as the type of gearbox, the design of the gears, the quality of manufacturing, and the operating conditions. Sugar mill gearboxes are often subjected to heavy loads and high speeds, which can contribute to higher noise levels. The noise generated by gearboxes is typically categorized into two main components:

- Mechanical Noise: This is the noise produced due to the interaction of gear teeth as they mesh and transmit power. The impact and sliding between gear teeth can result in vibrations and noise. Helical and bevel gearboxes tend to generate less mechanical noise compared to straight-toothed gears.

- Aerodynamic Noise: In some cases, the movement of air around the gearbox can contribute to noise generation. This can be more pronounced in open or poorly enclosed gearbox designs.

To mitigate noise levels, manufacturers implement various techniques:

- Precision Manufacturing: High-quality manufacturing processes result in gears that mesh more smoothly, reducing impact and vibration.

- Gear Tooth Design: Optimized gear tooth profiles, such as helical or spiral bevel gears, can help minimize noise by promoting smoother meshing.

- Lubrication: Proper lubrication is crucial to reducing friction and noise. High-quality lubricants and effective lubrication systems can help dampen noise levels.

- Enclosures: Well-designed gearbox enclosures and housings can help contain noise and prevent the transmission of vibrations.

- Vibration Damping: Adding vibration-damping materials or features can help absorb vibrations and reduce noise transmission.

It’s important to note that while efforts can be made to reduce gearbox noise, it’s challenging to completely eliminate it due to the nature of gear interactions. Regular maintenance, monitoring, and following manufacturer’s recommendations can help ensure optimal performance and noise levels.

Role of a Gearbox in a Sugar Mill

A gearbox plays a critical role in a sugar mill by facilitating the efficient conversion of power and torque, enabling the proper operation of various machinery involved in sugar extraction and processing. The gearbox serves as a mechanical device that transforms the characteristics of the input power to meet the specific requirements of the sugar milling process. Its primary functions include:

- Speed Reduction: The gearbox reduces the high-speed rotational motion generated by the input source, such as an electric motor, to a lower, more suitable speed for driving the sugar extraction equipment. This reduction in speed ensures that the machinery operates within its optimal range and prevents excessive wear and strain.

- Torque Increase: By reducing the speed, the gearbox simultaneously increases the torque output. This higher torque is essential for effectively crushing and extracting juice from sugarcane stalks, as well as driving other heavy machinery involved in the sugar milling process.

- Directional Change: In some cases, a sugar mill gearbox may also be responsible for changing the direction of rotational motion, allowing the machinery to operate in different orientations or perform specific tasks.

- Power Distribution: The gearbox distributes the transformed power and torque to various parts of the sugar mill, such as the rollers, crushers, and conveyors. This distribution ensures that each component receives the necessary energy to perform its intended function.

- Control and Regulation: The gearbox allows operators to control the speed, torque, and direction of the machinery within the sugar mill. This control is essential for maintaining consistent and efficient processing while adapting to varying operating conditions.

Overall, the gearbox is an integral component that optimizes the interaction between the input power source and the sugar extraction equipment. Its ability to adjust speed, torque, and direction ensures that the sugar milling process is carried out effectively, resulting in higher productivity and quality in sugar production.

editor by CX 2023-09-15