Product Description

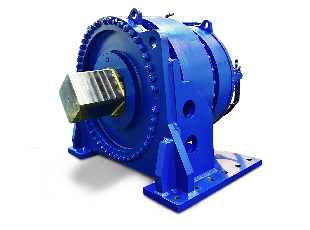

Starshine Drive NCJ Series Helical Geared Motor

Product Description

Features:

- High efficiency and energy saving: low energy, low noise, small vibration, low temperature rise, wide output speed, and high efficiency: 92%-96%.

- With wide variable range of voltage and frequency motor from 20HZ to 60HZ, and voltage from 320V to 420V.

- Modular design with strong interchangeability.

- Iron or aluminum casting house, good rigidity, high strength and excellent heat-loss.

- Advanced design: gear pair processed by carburizing and quenching heat treatment, and unique low noise gear tooth design to ensure the service life.

- Free maintenance: special lubrication to guarantee normal running for 20,000 hours without oil replacement;

- Easy replacement: can replace cycloid gearbox and upgrade product

Technical parameters

| Type | Old Type | Output Torque | Output Shaft Dia. |

| SNR02 | NCJ02 | 130N.m | φ22 |

| SNR03 | NCJ03 | 250N.m | φ28 |

| SNR04 | NCJ04 | 500N.m | φ32 |

| SNR05 | NCJ05 | 750N.m | φ40 |

| SNRW03Y | NCJT03Y2 | 250N.m | φ35 |

| SNRL04Y | NCJF04Y2 | 450N.m | φ35 |

About CHINAMFG Drive

ZheJiang CHINAMFG Drive Co.,Ltd(Starshine) have a strong technical force with over 350 employees at present, including over 30 engineering technicians, 30 quality inspectors, covering an area of 80000 square CHINAMFG and kinds of advanced processing machines and testing equipments. We have a good foundation for the industry application development and service of high-end speed reducers & variators owning to the provincial engineering technology research center,the lab of gear speed reducers, and the base of modern R&D.

Our products are widely used in ceramic industry, glass industry, woodworking machinery , high voltage switch, food & beverage, packaging & printing, Storage & logistics, hoisting & transportation facilities…etc , and CHINAMFG technically provide the professional product & service for the medium and high-end customers, and our gearboxes are best-selling in domestic, and even in abroad , such as in Europe, North America, South America, Middle East, South Asia, Southeast Asia, Africa…etc.

In the future , CHINAMFG will hold the creed of “serving customer, diligence & simplicity, self-criticism, innovation, honesty, teamwork”, and the concept of “quality creates value” to focus on the customers’ requirements and provide them the competitive transmission solution and create value for them constantly, and make a high-end equipment manufacturing industry and create a preferred brand of replacing import products and upgrading continuously for the end users.

Team

Quality Control

Quality:Insist on Improvement,Strive for CHINAMFG With the development of equipment manufacturing indurstry,customer never satirsfy with the current quality of our products,on the contrary,wcreate the value of quality.

Quality policy:to enhance the overall level in the field of power transmission

Quality View:Continuous Improvement , pursuit of CHINAMFG

Quality Philosophy:Quality creates value

3. Incoming Quality Control

To establish the AQL acceptable level of incoming material control, to provide the material for the whole inspection, sampling, immunity. On the acceptance of qualified products to warehousing, substandard goods to take return, check, rework, rework inspection; responsible for tracking bad, to monitor the supplier to take corrective measures to prevent recurrence.

4. Process Quality Control

The manufacturing site of the first examination, inspection and final inspection, sampling according to the requirements of some projects, judging the quality change trend; found abnormal phenomenon of manufacturing, and supervise the production department to improve, eliminate the abnormal phenomenon or state

5. FQC(Final QC)

After the manufacturing department will complete the product, stand in the customer’s position on the finished product quality verification, in order to ensure the quality of customer expectations and needs.

6. OQC(Outgoing QC)

After the product sample inspection to determine the qualified, allowing storage, but when the finished product from the warehouse before the formal delivery of the goods, there is a check, this is called the shipment inspection.Check content:In the warehouse storage and transfer status to confirm, while confirming the delivery of the product is a product inspection to determine the qualified products.

Packing

Delivery

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery, Dumbwaiter, Sugar Mills, and Kinds of Equipments |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Lower Rotation Speed |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

| Customization: |

Available

| Customized Request |

|---|

Common Problems in Sugar Mill Gearboxes

Sugar mill gearboxes are subjected to challenging operating conditions and heavy loads, which can lead to various issues over time. Some common problems that may occur in sugar mill gearboxes include: wear and pitting, misalignment, lubrication issues, overloading, corrosion and contamination, seal damage, vibration and noise, gearbox overheating, bearing failures, and operational shock loads. Regular maintenance, proper lubrication, alignment checks, and timely addressing of any emerging issues are crucial to mitigate these common problems and ensure the reliable and efficient operation of sugar mill gearboxes.

Retrofitting Older Sugar Mills with Modern Gearboxes

Yes, it is possible to retrofit an older sugar mill with a modern gearbox to improve its performance, efficiency, and reliability. Retrofitting involves replacing the existing gearbox with a newer, more advanced model that meets the mill’s current operational requirements. The process typically includes:

- Assessment: Evaluating the existing gearbox and overall mill setup to determine the feasibility of retrofitting.

- Customization: Designing a modern gearbox that fits the mill’s specifications, including torque requirements, speed ratios, and mounting dimensions.

- Installation: Removing the old gearbox and installing the new one, which may involve adapting mounting points and ensuring proper alignment.

- Integration: Connecting the new gearbox to the mill’s existing machinery and systems, ensuring seamless operation.

- Testing and Calibration: Conducting thorough testing and calibration to ensure the new gearbox functions optimally and meets performance expectations.

- Training: Providing training to mill operators and maintenance personnel on the operation and maintenance of the new gearbox.

Retrofitting offers several benefits, including improved efficiency, reduced downtime, enhanced product quality, and extended equipment lifespan. It can also be a cost-effective alternative to replacing the entire mill. However, retrofitting should be approached with careful planning and engineering expertise to ensure successful integration and compatibility between the new gearbox and the rest of the mill’s components.

Role of a Gearbox in a Sugar Mill

A gearbox plays a critical role in a sugar mill by facilitating the efficient conversion of power and torque, enabling the proper operation of various machinery involved in sugar extraction and processing. The gearbox serves as a mechanical device that transforms the characteristics of the input power to meet the specific requirements of the sugar milling process. Its primary functions include:

- Speed Reduction: The gearbox reduces the high-speed rotational motion generated by the input source, such as an electric motor, to a lower, more suitable speed for driving the sugar extraction equipment. This reduction in speed ensures that the machinery operates within its optimal range and prevents excessive wear and strain.

- Torque Increase: By reducing the speed, the gearbox simultaneously increases the torque output. This higher torque is essential for effectively crushing and extracting juice from sugarcane stalks, as well as driving other heavy machinery involved in the sugar milling process.

- Directional Change: In some cases, a sugar mill gearbox may also be responsible for changing the direction of rotational motion, allowing the machinery to operate in different orientations or perform specific tasks.

- Power Distribution: The gearbox distributes the transformed power and torque to various parts of the sugar mill, such as the rollers, crushers, and conveyors. This distribution ensures that each component receives the necessary energy to perform its intended function.

- Control and Regulation: The gearbox allows operators to control the speed, torque, and direction of the machinery within the sugar mill. This control is essential for maintaining consistent and efficient processing while adapting to varying operating conditions.

Overall, the gearbox is an integral component that optimizes the interaction between the input power source and the sugar extraction equipment. Its ability to adjust speed, torque, and direction ensures that the sugar milling process is carried out effectively, resulting in higher productivity and quality in sugar production.

editor by CX 2024-04-03